The GeoCube is designed to be a trouble-free tool in the field

and the test results are intended to be easy enough to use by

operators with all of the detail necessary for Engineers to

confidently use the test results as part of modeling a

geothermal system. The questions below encompass the

majority of the inquiries that we receive before, during and

after the sale of the GeoCube. If you need something that

we don't cover here, please

contact us.

- I've run a test but am having problems with my computer. Can Precision assist with TC test reports?

- I'm Interested in using the Remote Data Logging. What do I need to know to make it work?

- Is the TC/TRT analysis software available on a standalone basis?

- Can we see examples of what happens when TC tests are disturbed or not set up properly?

- What causes format errors importing data to the GLD TC Analysis Module?

What are the different models of the GeoCube?

The GeoCube is offered in three standard configurations

plus an extended range model that varies based on the depth that the unit can serve. The depth capacity (500'/150m,

850'/260m,

1,100'/335m) is determined by the pump, other hardware, heating elements and electrical system design that are associated with each model. The heating capacity is determined by the amount of power that needs to be injected per foot, per ASHRAE guidelines.

By design, The GeoCube is able to inject 15-25 watts/foot or

49-82 watts/meter of borehole for the model that is selected.

The user can select from multiple heater powers to supply the appropriate power to deliver the heat injection for their specific test borehole.

The

extended range models

are available with all of the same logger configurations using a

larger capacity heat exchanger and additional heating elements

to allow testing of very deep boreholes.

Can the GeoCube perform

TC/TRT tests in all times of

the year?The time of year does not have a direct relationship to

vertical borehole

TC/TRT test. The GeoCube is internally insulated to

minimize impact on the circulating liquid so as not

to be heated or cooled by changes in ambient temperature. The loopfield lines always should be insulated to prevent the loopfield lines from directly exchanging heat with the air. The GeoCube also may be blanketed if desired although the GeoCube does not require additional insulation.. The data analysis takes into account the heat energy from the heating elements and the circulating pump to determine the thermal conductivity/thermal

response results. In other words, the thermal conductivity/response data will accurately reflect the borehole and surrounding soil characteristics regardless of the time of year.

In colder climates, an appropriate antifreeze solution may be necessary to prevent freezing of the liquids when the test is being setup or when the test is being taken down.

The surface temperatures have essentially no short

term effect on boreholes that are deeper than 30

feet, so it is only important to take care of pipes

or liquids which are exposed at the surface.

In subfreezing temperatures, it will be necessary

either put antifreeze into the loop or drain to

sufficient depth to keep the liquid below the frost

line when the test is completed.

What test standards are used by the GeoCube to

determine TC/TRT Data?In North America, ASHRAE guidelines are the accepted standard for determining the thermal conductivity of a borehole. The data analysis that is used by the included software

(GLD) is based on the line-source analysis methodology described in

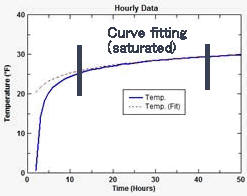

ASHRAE 111-8TRP and specified in the ASHRAE 2007 HVAC Applications Handbook - Chapter 32.12-32.13 The software produces a report that provides working definitions and explanations of how the data are analyzed and used. The standard test accurately (and optionally) will estimate the undisturbed loopfield temperature and will calculate the soil thermal conductivity of the loopfield. Tests typically are a minimum of 40-60 hours in duration., During the initial 12 hours of the test, heat from the GeoCube fully saturates the borehole,

which provides data for determining the Borehole Thermal

Resistance. During the remainder of the test, heat radiates out from the

saturated borehole and provides data for thermal conductivity determination using the previously mentioned standard line-source method. Precision Geothermal has published a paper titled,

"What to Look for in Thermal Response / Conductivity

Test Services". This document describes procedures,

standards and recommendations for performing Thermal

Conductivity / Thermal Response (TC/TRT) testing.

The GeoCube and related software provide data which may be

analyzed by other methods. Precision Geothermal uses

industry adopted theory for analyzing the test data and any

other analysis methods employed will need to use software or

methods not supplied by Precision Geothermal.

Why is it important to have the Undisturbed Ground Temperature?The undisturbed Ground Temperature is used to calculate the

Borehole Thermal Resistance. This is an important variable

in the design of a loopfield and can only be computed if an

accurate measurement of the Undisturbed Ground Temperature is

recorded prior to disturbing the borehole with the injection of

heat. Typically, the TC test is done a minimum of (5) days

after the drilling or a previous test to allow the borehole to

return to a steady state. Note that the Undisturbed Ground

Temperature is not used in the computation of the Thermal

Conductivity/Resistivity and does not change the TC value.

With the GeoCube, we recommend that the operator start the

datalogger and turn on the circulating pump for about 10 minutes

to completely mix the fluid in the loop and GeoCube to establish

the Average Undisturbed Ground Temperature prior to turning on

any heaters. If this step is not performed, the Average

Undisturbed value may be computed by dropping a manual

temperature probe and measuring the water temperature every 25

feet and averaging the results.

Do I have to

use special grout in the test borehole to get

good TC/TRT data?An experienced driller understands the importance of grouting boreholes and it is a requirement of IGSPHA and NGWA. This answer is intended to respond to the need for a "special" grout when doing

TC/TRT testing.

The borehole may be any size that is appropriate to drill and the borehole should be grouted with material that is suitable for the project. A typical TC/TRT test will try to simulate exactly what will be used for the future loopfield so that the test boring can be incorporated into the production system. The thermal conductivity testing results are not affected by the borehole, since the

TC/TRT. result is a measure of the thermal characteristics of the earth surrounding the loopfield and not the borehole itself. The testing analysis will disregard the first 12 hours of data as the borehole and loop piping heats up and thermally saturates. For the purpose of the testing, a borehole does need some kind of grout because air gaps between the pipe and borehole will effectively insulate the pipe from the borehole, which will likely devastate loopfield performance. The

TC/TRT test does not test the borehole, the loop pipe, the grout or the type of fluid that is used. A

TC/TRT test is testing the thermal characteristics of the earth that surrounds the borehole. The type of grout does however effect the "borehole thermal resistance" which also is calculated from the test and should be representative of the production loopfield design for the project that is being planned. Good commercial loopfield design software can utilize both the Thermal Conductivity

/ Thermal response data AND the Borehole Thermal Resistance data from a test loopfield.

What is a data logger??A data logger is an electronic instrument that records measurements such as temperature, voltage, pressure and events over time.

Typically a data logger is a small, battery-powered device that is equipped with a microprocessor, data storage capacity and sensors. Most data loggers utilize purpose specific software on a PC to start the logger and view the collected data. Data loggers are used in remote areas or anywhere you need to record measurements using a compact, convenient, self contained and battery powered unit. They are ideal for field studies, monitoring, testing and general research. The data logger in the GeoCube eliminates the need for a full PC system to be dedicated to the test site and allows data to be shuttled between the test and the user's computer by means of a physical shuttle or through GSM telemetry to an internet data site.

The GeoCube data logger records data for

the date and time; generator voltage; current; entering and return fluid temperatures;

fluid flow rate; logger battery status. The GeoCube comes with

software to download the datalogger readings in a CSV file and a custom software module from GAIA Geothermal that

can analyze the data on any Windows based PC. This module can read the data logger data and present a time analyzed output which documents the test conditions and outputs with test conclusions for use in geothermal loopfield designs. This data also can be analyzed using a text or spreadsheet program if so desired.

The datalogs may be recorded in either imperial or metric units.

The data logger is specifically matched to the sensors in the

GeoCube.

I've run a test but am having problems with my computer. Can Precision assist with TC test reports?Owners of the GeoCube™ thermal conductivity tester and customers that lease

a GeoCube thermal conductivity testing unit, may optionally contract with Precision Geothermal, LLC for services related to the retrieval and processing of data for an individual TC Test.

Generally, a customer is able to do their own data retrieval and processing with the provided tools. We understand that there are situations which may be related to

customer computers, users or operation that may require assistance beyond regular support. In these situations, Precision Geothermal, LLC will provide, at an additional charge, assistance to retrieve and process the data from a customer test.

This service is NOT design assistance and is NOT intended to substitute for individualized analysis of geology, test conditions or

evaluation of test data for varying subsurface conditions in potential loopfield locations.

In short, Precision Geothermal can assist when the need arises.

The customer is ultimately responsible for their own TC Test but

we can assist with the nuts and bolts of retreiving data and

generating the test report.

I'm Interested in using the

Remote Data Logging. What do I need to know to make it

work?The Advanced GSM Data Logger allows the user to send data to a

datalog website in real time. The web data service is

managed by HOBOLink, the manufacturers of the data logging

hardware. When a GeoCube is purchased with this option,

the user will send data to and from the GeoCube via the HOBOLink

web site as opposed to the use of a manual data shuttle.

This can be extremely useful for monitoring a test while it is

in operation without visiting the site during the test. It

is NOT a substitute for security at the test site and does

require some additional steps to insure that the test is run

properly. Rather than to discuss the advantages of having

the remote data, here are some considerations to consider before

selecting this option:

-

Reliable cell service is

necessary for the remote exchange of data. Not all

areas have good cellular data coverage.

-

The use of the HOBOLink data

service is the responsibility of the customer for service

after the first year. Precision Geothermal will set up

your account and the first year is included in the purchase.

Subsequent service after the first year is the

responsibility of the GeoCube customer.

-

The launch of the data logging

and the logging configuration is performed via the web and

requires that the operator have the necessary equipment on

site to launch and configure the test. An alternate

method requires the person that is operating the test to be

in contact with someone at their home base to launch the

data logging and to do the test configuration. This

procedure could be considered to be more complicated than

running the test with a non-telemetry logger but is the

choice of the company that is running the test.

-

The GSM Data Logger option

does NOT provide the ability to make any adjustments during

the test. The web site can communicate with the GSM

Data Logger but it cannot be used to make adjustments to

heaters, pump operation or etc.

-

The GSM Logger needs to be

charged to maintain communications for the duration of the

test. If you operate a cell phone, you already

understand the importance of having a full charge on your

battery. The variability of the job site power is

generally not condusive for a "universal" charging solution.

The GSM data logger is a powerful

tool for those that must be able to remotely monitor their test

data.

I want

to use shore power instead of renting a generator. Why is

that not recommended?A successful TC/TRT test requires reliable, consistent power in

order to maintain data validity. "Shore Power" or

commercial power can have variations of up to 20% in normal

operations. Utilities deal with wide ranges of load

conditions and it is not uncommon to see brownouts in the system

or power surges that will invalidate the data for your entire

test. Below find a report dialog from using an "unstable"

power source that has exceeded the +/- 10% threshold that was

set for the test: The graph clearly shows the instability

and the resulting "wobbles" in the temperature.

Results like this are clearly unacceptable. We recommend

using a diesel powered generator that is 2X the load for most

optimal results.

Based on the standards from ASHRAE and IGSHPA, a proper test must maintain a maximum +/- 1.5% power input standard deviation from the average power level. Peak variations must be kept at less than 10% of the average power level.

Can I use a 60Hz unit with a 50Hz power source or vice versa?No, the GeoCube is designed and shipped to use a specific type

of power source. Pumps are designed to run at a particular

frequency as well as a specific voltage. The RPM of an

induction motor is based on the frequency of the power source.

GeoCubes are shipped with heating elements that are specifically

rated to produce a specific wattage at their design voltage.

While a GeoCube may operate at a higher/lower voltage or

higher/lower frequency, our ratings are for specific components

to be used in the conditions that they were designed for.

Does it make any difference if I use plain

water instead of an anti-freeze solution?The GeoCube can use plain water or an antifreeze solution. The T.C. test results will not be affected if the environment calls for a solution that involves propylene glycol or ethanol (for example). The GeoCube will maintain adequate flows with antifreeze solutions and the mathematics used to determine the TC value are not affected by whether the test is run with water or antifreeze. If the testing is being conducted in cold climate conditions, steps should be taken to insure that freezing does not occur in the exposed loopfield piping or the GeoCube. Normal ground temperatures will protect the standing liquid below the surface. Exposed portions of the pipe should be protected with antifreeze or kept dry before and after the testing is completed. The GeoCube should be drained completely between uses.

Why do I have to run

tests for 40 hours? Can't I perform shorter tests that are

just as accurate?

Standards for thermal analysis of the earth surrounding a borehole have been developed over the years by studies which have been used by organizations like ASRAE and IGSPHA. These empirical tests have been established to provide a meaningful and consistent test that does not attempt to extrapolate data beyond the norms that have been established.

A typical borehole and surrounding formation takes 12-20 hours

to saturate at the rate of heat injection that is used.

The TC/TRT value is based on finding a "steady state" slope of the

temperature curve once saturation is achieved. Testing equipment such as the GeoCube and testing organizations that provide

TC/TRT. tests as a third party service are not creating the science but are following the accepted standards. While shorter tests will provide data, the results may not be acceptable by an engineering firm that must use the data to do a project design In addition to the duration of the test, the test also must be continuous and may not be stopped and restarted without waiting for a minimum of (5) days for the earth to rreturn to its native, undisturbed state. Test operators are well advised to take precautions to make sure that generators have sufficient fuel to last the entire duration of the test since any interruption likely will require the test be completely re-run.

For a summary of recommended conditions, please view our

published guidelines:

"What

to Look for in Thermal Response / Conductivity Test Services"

Standards for thermal analysis of the earth surrounding a borehole have been developed over the years by studies which have been used by organizations like ASRAE and IGSPHA. These empirical tests have been established to provide a meaningful and consistent test that does not attempt to extrapolate data beyond the norms that have been established.

A typical borehole and surrounding formation takes 12-20 hours

to saturate at the rate of heat injection that is used.

The TC/TRT value is based on finding a "steady state" slope of the

temperature curve once saturation is achieved. Testing equipment such as the GeoCube and testing organizations that provide

TC/TRT. tests as a third party service are not creating the science but are following the accepted standards. While shorter tests will provide data, the results may not be acceptable by an engineering firm that must use the data to do a project design In addition to the duration of the test, the test also must be continuous and may not be stopped and restarted without waiting for a minimum of (5) days for the earth to rreturn to its native, undisturbed state. Test operators are well advised to take precautions to make sure that generators have sufficient fuel to last the entire duration of the test since any interruption likely will require the test be completely re-run.

For a summary of recommended conditions, please view our

published guidelines:

"What

to Look for in Thermal Response / Conductivity Test Services"

Note: There have been papers published in Europe

suggesting that there are "electrical response method" tests

which can do the same job in less than an hour. At this

time, the industry accepted standards which actually measure and

observe a physical heat exchange are still the trusted method.

With the GeoCube, everything needed to produce a reliable and

accurate test is provided along with the peace of mind that

TC/TRT test will produce accurate results without any additional

exotic equipment or reliance on others to interpret your data.

Why is it best to run 2 minute sample periods? What if I

want to have a longer or shorter sample period?

The sample period of two minutes is recommended to allow the

test to collect sufficient data and also to allow the flow

pulse counter accuracy to produce acceptable results.

For analysis purposes, tests must use at

least one minute samples, but to measure flow

accuracy in the 5-10% range, tests must use two minute

samples or longer. This is a math issue and not a flow

accuracy issue. Because a pulse counter is measuring

an integer value of volume per pulse, the longer sample

period means that flows which are not an exact integer

volume per minute will always have count differences from

one period to another. With the longer sample period,

a difference of one count will be statisticly less

significant against the larger flow count value from a

longer sample. The test requires uniform flows and the

volume per minute value that is computed needs to have an

accuracy of +/- 5% or better for a valid test. With

the expected flows of 7-10 GPM with a typical GeoCube

configuration, a sample period of two minutes or longer is

needed for a good qualitative flow result. Tests can

be run with samples of 2 minutes to 5 minutes with good

results.

If you have accidently set your sample

period to one minute or less, please contact us and we can

assist with correcting the sample period in the recorded

data.

It gets very cold at night and hot during the

day. Don't I have to keep the GeoCube in an insulated trailer?Some users build their GeoCube into an insulated trailer.

Most users that are looking for portability and flexibility do

not. Keep in mind that direct sunlight which impinges on

the GeoCube or especially on uninsulated connecting pipes can

influence the test readings, much like a car that sits in the

hot sun. While we internally insulate the GeoCube with a minimum of 2" of Formular® 250 insulation to shield the sensors and piping

to minimize the influence of outside temperature swings,

an insulating blanket or shading can help further minimize the effect. The exposed loopfield piping,

if uninsulated, is a larger source of temperature variation than the GeoCube. Exposed pipes should be

always be fully insulated and only the shortest necessary amount of pipe to make the connections should be used. The photos below show GeoCubes in operation with insulation applied. If available,

a thermal blanket such as used in construction may be used to cover the pipes for maximum protection. Insulation of the connecting pipes in ALL climates and seasons is the correct way to run conductivity/response tests.

It is always prudent to protect the unit from direct solar radiation during the test.

What are examples of test

results that show problems with the setup and operation of the

GeoCube?While it is

quite easy to do a test correctly, here are some examples of what a correct

datalog will look like along with examples of different problems that

can cause a test to be compromised:

|

This is

an example of a test that has completed properly. |

| |

|

|

|

Flow and

Temperature plotted. Note issues leading up to

hour 18. User introduced additional water into the

pump well. Loop was likely not purged properly

prior to starting the test. |

|

|

Flow rate changed

around 30 hours into test. Likely air bubble. |

|

|

Power and

temperature plotted. Generator is poorly

regulated. |

|

|

Uninsulated loop

pipes exposed to direct sunlight. Causes a small

bump in the temperature profile. |

|

|

Properly run test

in borehole with flowing water. Note the

temperature delta from undisturbed is about half of what

is expected in a normal test. |

|

Can I see examples of different versions of the GeoCube

The GeoCube is offered in three standard configurations

plus an extended range model that vary based on the depth that unit can serve. The depth capacity (400'/120m, 500'/150m, 700'/220m,

850'/260m) is determined by the pump and heating elements that are associated with the model. These units appear

to be very similar from the outside and are the same physical

size. The Extended

Range GeoCube has an external access panel to the heaters. The heating capacity is determined by the amount of power that needs to be injected per foot, per ASHRAE guidelines. The GeoCube is able to inject 15-25 watts/foot

or 49-82 watts/meter of borehole for the model that is selected and the user can select the appropriate power to deliver the heat injection for their specific test borehole.

Our model ratings are based on 60Hz units with 240v available.

50Hz unit heaters are slightly derated. The pumps, electrical system and thermal elements are sized appropriately for the

model of the GeoCube. A high capacity GeoCube may be used for shallower boreholes without any problem by selecting the appropriate power levels with the standard controls available in the unit.

While all three units have the same external configuration, customization options, including multiple finishes, connections and multiple data logging options, are available. All units share the same reliability levels for the basic functionality. Units with the Advanced Data logger feature offer extra protection for the electronic logging unit due to the waterproof internal housing for the electronics. Units that have the anodized chassis will retain their "new" appearance for a greater percentage of their lifetime and can stand up to everyday wear and tear to a greater extent than the polished finish of the standard unit. While the anodized chassis adds extra production to the unit, the performance is 100% the same as the standard finish. The anodized unit (below right) also shows the optional "H" valve assembly, which facilitates reliable start up and tear down by allowing the loops to be fully purged and filled. By reliably eliminating air from the test loop, you protect the integrity of the test and prevent accidental damage to heating elements which could be prematurely damaged by dry operation.

Redundant data sensors are available for every configuration and provide peace of mind during the critical hours of test operation. All redundant measurement channels operate independently and provide a fail-safe for malfunction of any individual data logger channel or unit sensor. This is an internal feature of the GeoCube and is not visible from the outside of the unit but is evident in the additional data points that are collected during the testing.

Our current software has built-in testing to automatically

select sensor pairs from the test data in the event of any

sensor failure or disconnection during a test.

The Advanced Data Logger option with GSM telemetry requires no external antenna and is fully protected inside of the locked housing. This option provides for real-time remote reading of data from your GeoCube during any test conducted in a location with cellular coverage. All loggers collect and store the full data set even if the coverage of the GSM is weak or spotty at the project site.

GeoCube - Standard Finish

|

GeoCube - Anodized Finish

|

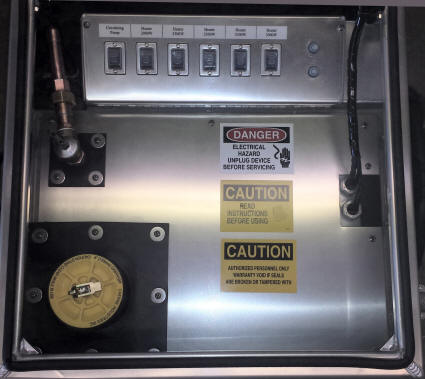

Extended Range Unit Top Panel

|

Standard Pump/Heater Panel

Extended Range Pump/Heater Panel

|

GeoCube with Advanced Data Logger |

GeoCube with Standard Data Logger

|

Why are there different types of data loggers for the GeoCube?

The loggers in all GeoCubes collect digital data that are stored in flash memory inside of the logger. The standard data logger can store multiple tests and can stay in the unit for extended periods of time for later retrieval. Since a

TC/TRT test involves routine handling in outside environments and with exposure to liquids, some customers prefer to minimize accidental exposures to moisture. The Advanced Data Logger offers a waterproof housing internal to the GeoCube as well as the ability to provide optional telemetry for projects that require real-time readouts of data points. The GSM option for the Advanced Data Logger provides for communication via commercial cellular coverage and data are received by an FTP site for viewing over the web. There are no exposed antennas visible on the GeoCube, which protects the logger unit and eliminates unnecessary attention when the unit is unattended in the field. The subscription service that comes with the GSM logger option provides for secure, backed up data storage that can be read from anywhere in the world.

Advanced Datalogger -

Waterproof Internal Housing |

Standard Datalogger

(removeable) |

Does the Convenience Panel Meter Tell Me if the Logger

is Running?

The convenience meter in the panel is for user "CONVENIENCE".

While it provides accurate information regarding the power from

the generator and the operation of the GeoCube heaters, it is

NOT connected to the data logger and does NOT reflect what is

happening with the data logger. The data logger and the

convenience meter are totally independent of each other.

All tests and logging operations must be started using the data

shuttle or the logger. The convenience meter was a user

requested feature for quick monitoring of a test after the data

logger has been properly set up and launched.

For more information on the convenience meter, see the

Convenience Meter Information

What is the Accuracy of the GeoCube?

The GeoCube utilizes a data logger system with sensors that have been tested and approved for the particular logger included with the GeoCube. Depending on the model of the sensor, there will be several types of sensors that are applied in different locations within the unit. Units that employ redundant temperature sensor sets will have multiple sensors that measure loop temperature in multiple locations within the GeoCube. Our sensors exceed the requirements of ASHRAE and IGSHPA standards.

-

Voltage: Accuracy ±1%

from 10% to 130% of rated voltage (AC Potential transformer)

-

Current Sensing:

Linearity accuracy ± 1% from 10% to 130% of rated current

(AC Current Transformer)

-

Flow Meter: Accuracy -

AWWA spec, 97 - 103% (Pulse Output Flow meter)

-

Temperature Sensor: <

+/-0.2 deg C in 0 to 50 deg C operating range - 12 bit smart

sensor

Note: The primary and

redundant sensors will NOT read the exact same temperatures due

to their mounting locations and initial calibration from the

factory. They will exactly track temperature variations to

provide a fallback in the event of sensor failure, data channel

failure or momentary

bubble in the fluid path.

Do I have to periodically recalibrate the GeoCube

temperature sensors?

The simple answer is

NO. This is by

design of the GeoCube and a frequent question from users.

Disclaimer: Any

sensor can be NIST tested for calibration. With our

hardware, we sought to avoid the need for the user to have to go

through this expense. Your calibration results will be

within the specs listed above OR the sensors will not work at

all. Any user that insists on needless "calibration" for

the sensors we use should consider just installing new sensors.

The cost of removal and certification may be more costly than

just installing new sensors and the process is somewhat wasteful

for all involved. There is NO calibration of this type of

sensor.

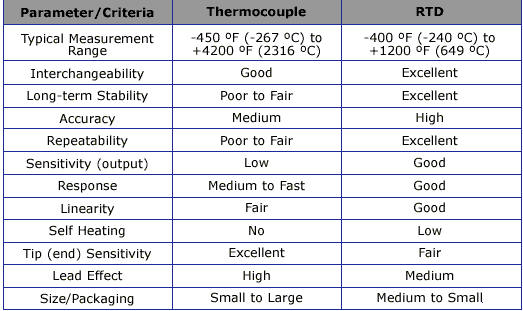

The GeoCube utilizes RTD type sensors that are

specifically matched to the model of datalogger that is

installed in the GeoCube. The RTD sensors are guaranteed

to maintain drift accuracy during their operational life and the

exact same sensors are also used in other applications that are

temperature critical, such as FDA certified tracking and

traceability. Other TC/TRT test systems often use

thermistor or thermocouple type sensors. The advantage of

the RTD sensors that are used in the GeoCube is that they have

incredibly stable drift characteristics compared to thermistors

or thermocouple sensors. In our application, the main disadvantage of the RTD

sensor is that they can cost 10x to 50x more than thermistors or

thermocouples.

The GeoCube designers chose to use

the RTD type sensors because they do not drift, have a wide

operating accuracy range and because the TC calculations are

based on the delta T between the supply and return and not the

absolute temperature. The critical temperature is between

the sensors. The GeoCube is intended to be user-friendly,

reliable and only require minimal service to guarantee accurate

test results. Each temp sensor is electronically matched

to the data logger, serialized for traceability and is highly

accurate. The sensor is either good or bad. There is

no drift.

Note: As described above in

the accuracy section, the primary and backup sensors will NOT read the exact same temperatures due

to their mounting locations. They will exactly track temperature variations

between pairs to

provide a fallback in the event of connector failure or loss of

channel data in either pair.

What can go wrong with a GeoCube?

Quite simply, the most likely thing to go wrong with the GeoCube itself is damage

caused by improper operation. The internal components have been selected for accuracy,

reliability and rugged use in the field. The mechanical parts most vulnerable to

user-induced damage are the pump and the heating elements.

Introducing mud and

gravel into a loop will kill most pumps. GeoCubes shipped after November 1, 2011 contain

a stainless mesh filter in the standpipe assembly to catch the unknown sediment or gravel

that have inadvertantly found their way into the loop pipe. Units with the 4" standpipe

that were purchased prior to November 2011 can use the new filter, which is available as

a replacement accessory. The mesh filter protects both the

pump and the flow meter.

Accidently restricting flows to the

heaters inside the GeoCube will cause the high-temp cutout circuits to trip or

worse, cause the heating elements to burn themselves out. One of the most common

mistakes is to burn out a heating element by not purging the loopfield and cube

properly prior to turning on the heating elements. Precision Geothermal offers

an optional "H" valve assembly for making it easy to properly purge a system prior

to starting the test but even this requires that the operator take proper steps to

eliminate air from the system.

Just like running an engine without oil - running the GeoCube heaters without properly

proper purging is a near certain guarantee of damage or shortened life. Your GeoCube

is an investment worthy of proper care and operator training. With proper operation,

your GeoCube will provide years of reliable service.

GeoCubes (with the redundant sensor option) shipped after

October 1, 2013 now feature redundant sensor wells in the fluid

flow instead of the pipe mounted sensors in earlier models.

Extended Range GeoCubes feature an external panel for access to

heating elements and a stainless steel heat exchanger manifold.

The driller introduced mud and sand into the test loop.

How can I protect the GeoCube?

Precision

Geothermal has repaired a number of units that were returned

after failure due to gravel and sand clogging the pump and

causing damage to the pump and the heaters. The current

product design now incorporates a built in, cleanable, stainless

steel filter assembly. This filter will catch sand and

gravel before it can get into

the GeoCube and will help prevent damage from sediment that was

introduced by the driller or through vandalism. Older

units will also accept the new filter system and may be field

upgraded by ordering a replacement filter assembly. Our

filter is rated nominal 140 micron and will stop particulates .0055" and larger while allowing

for full rated pump flows.

Precision

Geothermal has repaired a number of units that were returned

after failure due to gravel and sand clogging the pump and

causing damage to the pump and the heaters. The current

product design now incorporates a built in, cleanable, stainless

steel filter assembly. This filter will catch sand and

gravel before it can get into

the GeoCube and will help prevent damage from sediment that was

introduced by the driller or through vandalism. Older

units will also accept the new filter system and may be field

upgraded by ordering a replacement filter assembly. Our

filter is rated nominal 140 micron and will stop particulates .0055" and larger while allowing

for full rated pump flows.

Why can't I import my CSV file correctly into the Ground Loop Design TC analysis software?

Importing the test result CSV file is generally a straight

forward process. Since the GeoCube is often used in many

parts of the world, the standards for the data format can

present unexpected results. With Windows OS, the Region

selected will set the data format that is seen by the software.

GLD requires that the Time/Date format be in Month/Date/Year

order and the time needs to be Hours/Minutes/Seconds.

Decimals need to specifiy fractions and if your region uses

commas, things will not work correctly. The quickest

workaround is to go the Regions setting in your Windows Control

Panel and select the correct formats or set the Region for

English (US) to see the correct settings. After setting

these settings as specified above, you should eliminate the

import errors that may be occuring.